“NO PROBLEM CAN WITHSTAND THE ASSAULT OF SUSTAINED THINKING.”

Voltaire

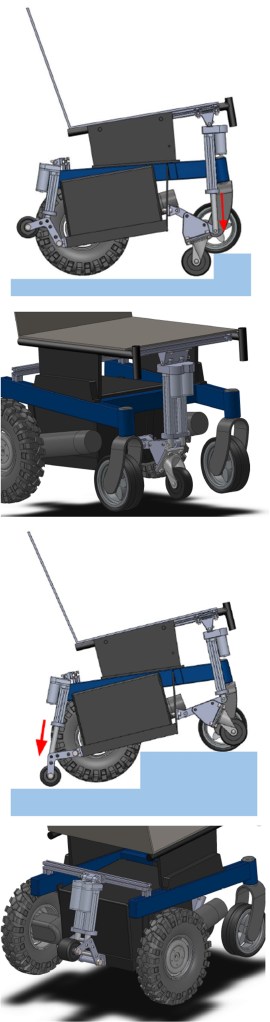

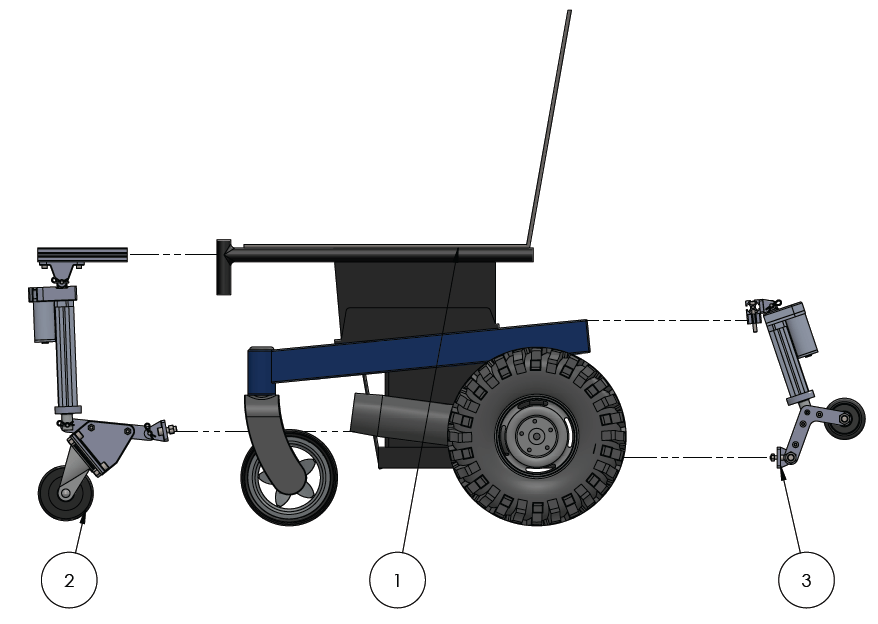

Curb Climbing System

UBC MECH 4th Year Capstone Project (2019-2020)

My final Capstone Design Project consisted of working in a team of 5 to deliver a fully-functional device that integrates with a Torque SP 3200 powered wheelchair, allowing its user to climb a single, 90-degree, 4” (100 mm) curb in collaboration with Tetra Society of North America.

- Created extensive technical documentation of the project: Gantt Charts, System Architecture Diagrams, and Function Decomposition Diagrams; manuals for assembly, operation, maintenance, and testing; technical reports, memos, and presentations

- Modeled, using SolidWorks, both device assemblies and parts which were then used to create exploded views, animations, simulations, marketing material, and technical drawings according to CSA standards

- Served as liaison between Tetra Engineers, the client, UBC MECH, and the project team, was responsible for cold-calling industry experts and users for additional resources

Backcountry Skiing Assistive Device

UBC MECH 3rd Year Design Project (2017)

My 3rd year Design Project consisted of working in a team of 5 to design, model, and analytically test an assistive device which would allow backcountry skiers to expend less energy while ascending back-country terrain.

- Performed extensive failure mode analysis on design iterations

- Presented a design proposal to a panel of professors with an accompanying 300-page technical report.

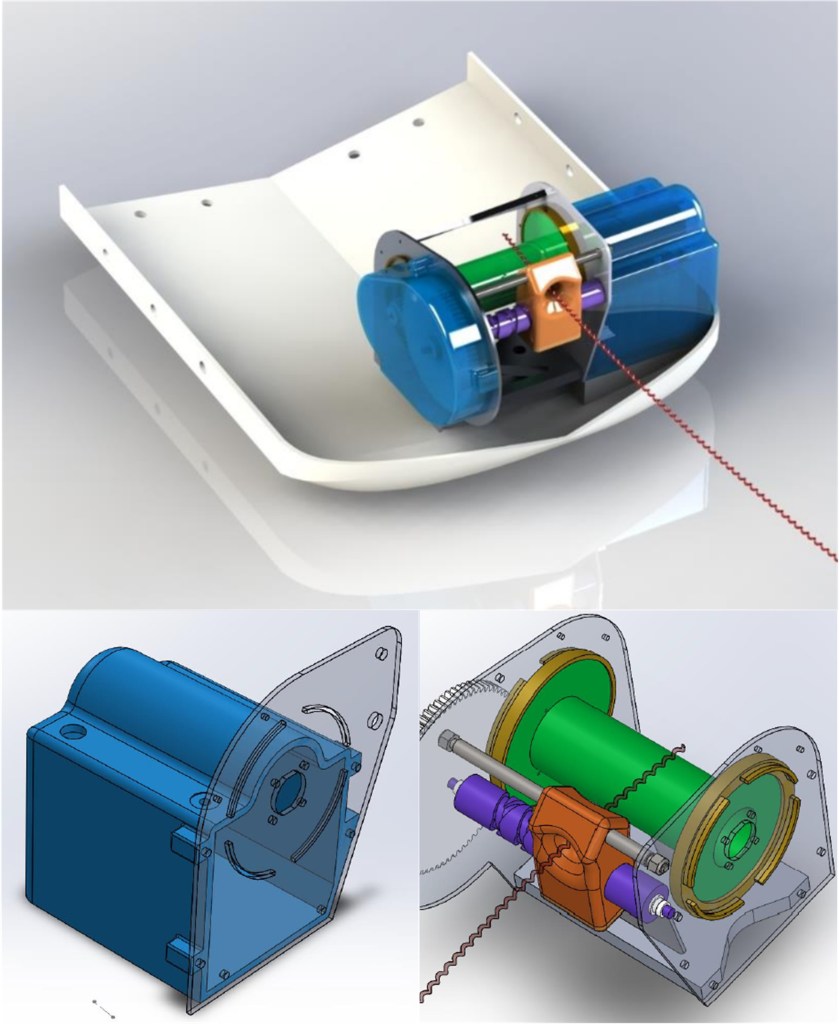

Assistive Technology

Makers Making Change (MMC) at the Neil Squire Society (NSS) (2017)

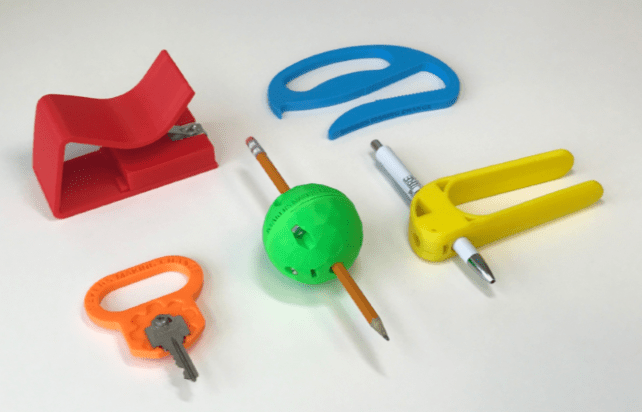

During my time working the MMC team at the NSS, I designed, modeled, and prototyped opensource assistive technology that would be published on the MMC Projects Database based on the suggestions of NSS clients and occupational therapists.

These low-cost, easy to fabricate items help with everyday tasks and promote independence whether it be writing, reading, cutting fingernails or carrying groceries.

- Created corresponding O&M documentation for each design

- Examples of these items include:

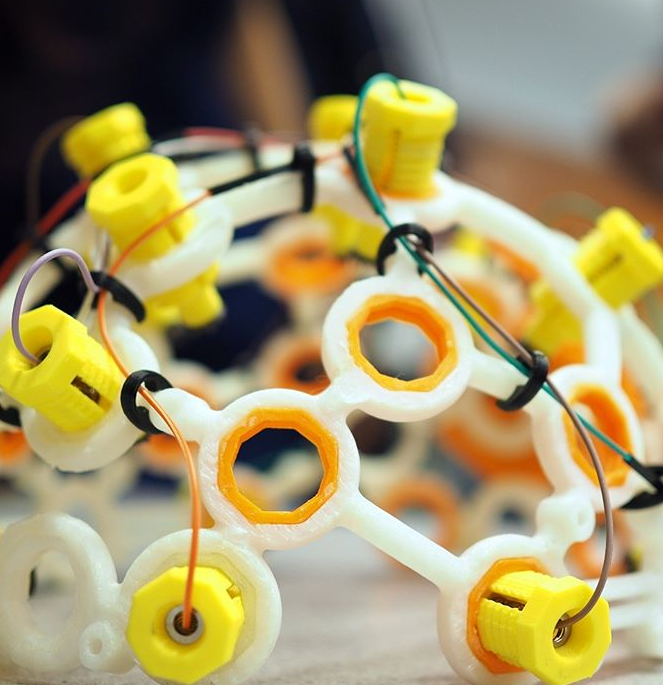

EEG Electrode Design

The Medical Innovation in NeuroTechnology team aims to build their capacity to tackle neurotechnology challenges, foster a collaborative network of professionals, enthusiasts and the general public. Goals also include bridging the clinical and social aspects of neuroscience by accessibly reproducing and innovating upon notable experiments and technologies.

- Explored rapid-prototyping fabrication methods such as 3D printing to obtain desired material properties (e.g., conductivity), simple assembly, and low costs

- Designed electrodes for optimal data collection while maintaining user needs and constraints such as user comfort, accessibility, hair, and longevity of the electrodes using SolidWorks

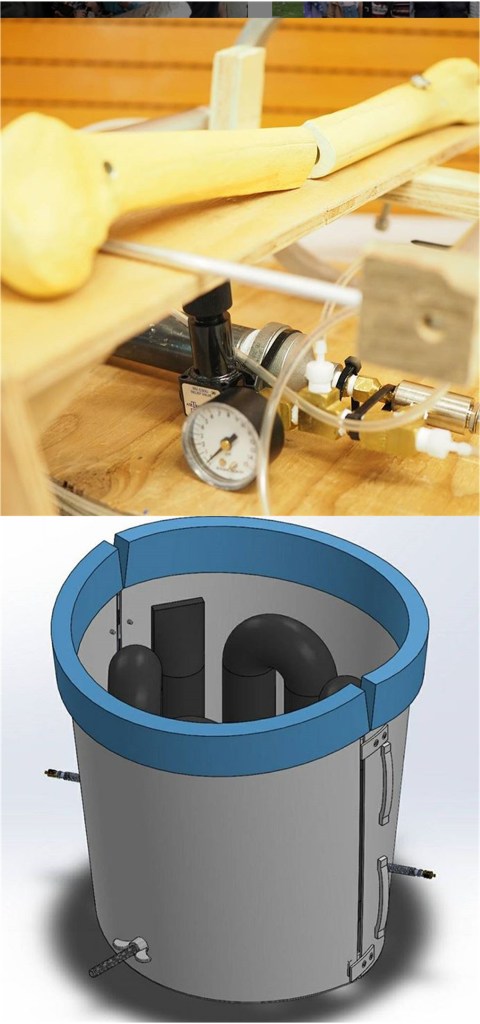

Femur Fracture Traction Device

UBC BEST – FFTP (2016-2017)

The Femur Fracture Treatment Project aims to design a mobile traction device for recovering femur fracture patients in low income countries where surgery is not easily accessible. Goals include better patient outcomes, increased mobility, and decreased hospital cost and bed time compared to current traction treatment.

- Used medical databases to research existing femur fracture treatment methods, epidemiology, and socio-economic factors for proper treatment in low-income countries

- Corresponded with experts in the field for insight on bone fracture mechanics and bone healing

- Physically (machine shop) and analytically (Fusion360) prototyped a traction device that focused on allowing earlier patient mobility for a shorter in-patient recovery time

Stroke Rehabilitation Device

UBC BEST – M2M (2016)

The Music 2 Movement team aims to develop an assistive music therapy device that makes the repetitive rehabilitation process in order for stroke patients to recover important daily functions more motivating and engaging.

- Conducted experiments using circuit analysis, MS Excel, and MATLAB to test the response of a “tap” assistive music therapy device

- Optimized device accuracy and sensitivity by exploring sensors, specifically piezoelectric fabric

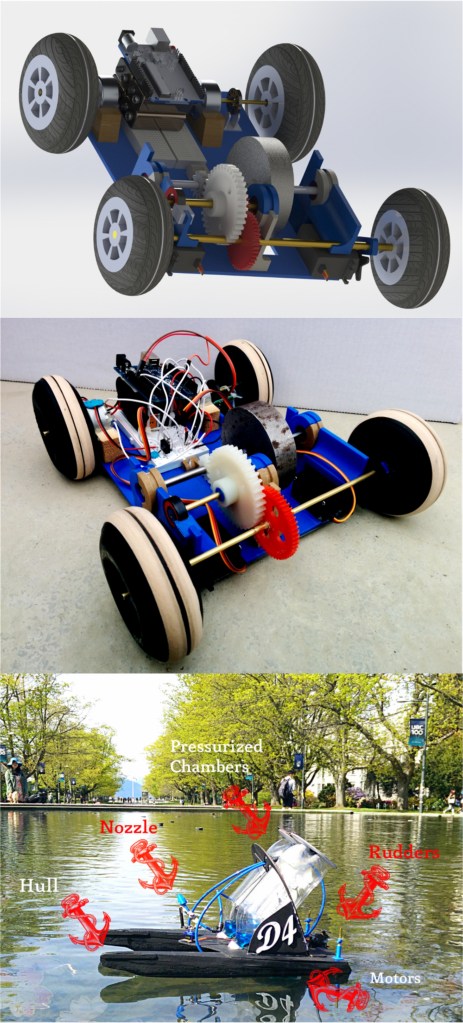

Fireboat and Autonomous Regenerative Braking

UBC MECH 2nd Year Design Project (2015-2016)

My 2nd year Design Project consisted of working in a team of 6 to create two prototypes: a quick response emergency vehicle capable of dispensing chemical retardant at fire situations and an autonomous vehicle that stored energy as it rolled downhill and breaked, then reused that energy for further propulsion.

- Managed timelines (MS Project), deliverables, and team operations in the prototyping of an autonomous regenerative braking vehicle and remote-controlled emergency fireboat

- Gained lab and software experience through the design and analysis of experimental data, achieving a more efficient design and a top 25 percentile result in competition; some examples of this for the fireboat design include:

- Optimized hull and rudder design to achieve smallest turning radius experimentally and quickest speed

- Analyzed data from experimental trials for optimum water carrying capacity and water shooting accuracy

- Set up electronic components of boat to control water delivery system and remote control

- Designed rudder control system using servo motors

Magnetic Levitation Device

UBC MECH 2nd Year Project (2015)

The MagLev uses a Hall Effect sensor (calibrated by two potentiometers) to detect a magnetic field created by a small magnet located at the bottom of the aluminum rod (floating object). This regulates the magnetic field being created from above by an electromagnet (copper coil) placed in the coil housing.

- Machined the structural components for the device using standard machine shop equipment, based on drawings and instructional blueprints

- Soldered components such as a hall effect sensor, potentiometers, resistors, and capacitors to a PCB

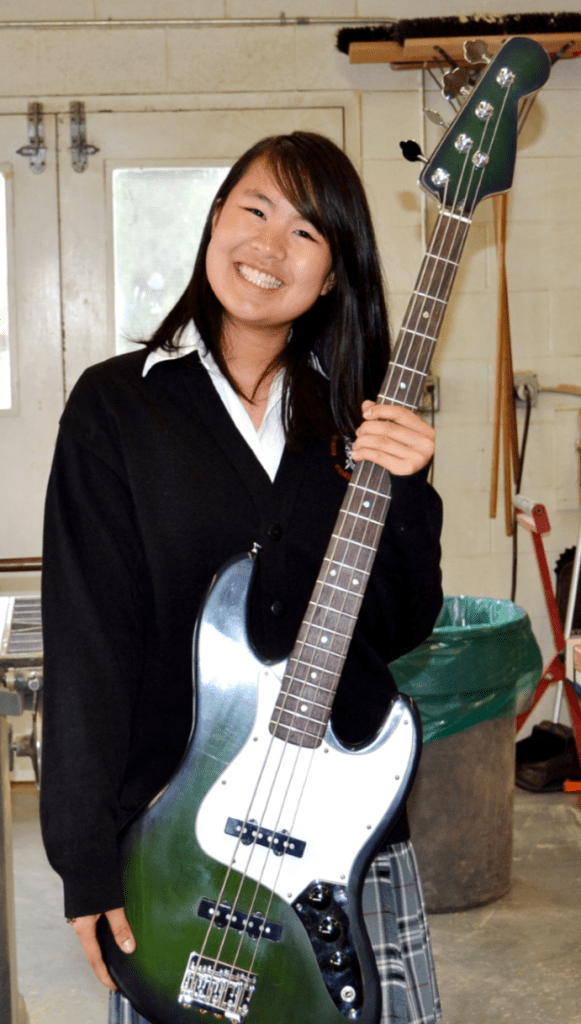

Guitar Building

High School Woodworking Projects (2012-2014)

My first guitar was a year-long project: a four string, solid body electric jazz bass. In my final year of high school, I completed a more challenging project: a custom, acoustic guitar complete with a smooth Venetian cutaway, a mahogany and spruce body, a rosewood fingerboard, bronze strings, walnut detailing and a black and white patterned binding. I designed the guitar with ergonomics in mind; therefore, its dimensions are slightly smaller than a typical acoustic guitar (e.g. the guitar’s neck fits my grasp).

For my high school carpentry, I received the District Dogwood Award for Carpentry and decided to pursue a career where I could utilize the skills I learned my experience guitar building.

- Designed, drafted, and constructed guitars under ISO standard with ergonomics and sound quality in mind, resulting in customised details, such as a smooth Venetian cutaway, mahogany and spruce body, and patterned binding

- Adjusted and tested electronics (for the electric jazz bass), frets, and bridge position for intonation, sound brightness, and fret buzz for a better quality product